This article explores the significance of anchor collars in fastening solutions, detailing their manufacturing process, applications, and benefits. As a leading manufacturer, Nanjing Taidun Marine Equipment Engineering Co., Ltd emphasizes the importance of these components in ensuring safety and stability across various industries.

This article explores the essential role of anchors for ships, detailing their types, functions, and maintenance. It emphasizes the importance of selecting the right anchor based on vessel size and seabed conditions, while also providing insights into anchor mechanics and the significance of the anchor rode. Nanjing Taidun Marine Equipment Engineering Co., Ltd is highlighted as a leading manufacturer in this field.

This article explores the manufacturing process, applications, and innovations in anchor chains, emphasizing the importance of quality and safety in marine operations. Nanjing Taidun Marine Equipment Engineering Co., Ltd is highlighted as a leading manufacturer in this field, committed to providing high-quality products that meet international standards.

This article discusses the essential role of anchor capstans in marine operations, detailing their design, functionality, and importance in anchoring, mooring, towing, and cargo handling. It emphasizes the need for regular maintenance to ensure optimal performance and safety. Nanjing Taidun Marine Equipment Engineering Co., Ltd is highlighted as a leading manufacturer of high-quality anchor capstans.

This article discusses the critical relationship between anchors and ships, emphasizing the importance of anchors in maritime safety and operations. It covers various types of anchors, their functions, and best practices for deployment and maintenance. Nanjing Taidun Marine Equipment Engineering Co., Ltd is highlighted as a key player in providing high-quality anchor products for the global maritime industry.

How to Choose the Best Marine Fenders: A Complete GuideMarine fenders are critical components in maritime safety, protecting vessels, docks, and offshore structures from impact and abrasion during berthing and mooring operations. Choosing the right marine fender is not just about cost—it’s about per

This article provides a comprehensive guide on selecting the right size fenders for your boat, considering factors like boat length, weight, and mooring conditions. It includes a sizing chart, tips for placement and maintenance, and answers to common questions about boat fenders. Proper fender selection and care are essential for protecting your vessel and ensuring safe docking.

This article provides a comprehensive guide on selecting the right boat fender size for optimal protection. It covers types of fenders, general sizing guidelines, factors influencing size selection, and maintenance tips. Proper fender choice is crucial for safeguarding your vessel during docking and mooring.

This article provides a comprehensive guide on selecting the appropriate fender size for boats, emphasizing the importance of protection, stability, and aesthetics. It covers factors to consider, types of fenders, installation tips, and answers to frequently asked questions, ensuring boat owners can make informed decisions for their marine needs.

This article provides a comprehensive overview of arch fenders, highlighting their features, benefits, and applications in the marine industry. It emphasizes the importance of arch fenders in protecting vessels and docking facilities, while also discussing installation and maintenance tips. Nanjing Taidun Marine Equipment Engineering Co., Ltd offers high-quality arch fenders as part of its OEM services.

This article discusses the significance of arch rubber fenders in marine safety, highlighting their features, applications, and benefits. Nanjing Taidun Marine Equipment Engineering Co., Ltd specializes in manufacturing these fenders, offering customization options to meet diverse needs. Proper maintenance and selection criteria are also outlined to ensure optimal performance.

Foam Filled Fenders: The Ultimate Guide to Enhanced Marine Safety and DurabilityMarine safety is a critical concern for boat owners, dock operators, and maritime professionals. One of the most effective solutions for protecting vessels and infrastructure is the foam filled fender. Unlike traditional

This article discusses the importance of fender cleats in marine operations, detailing their types, materials, applications, and benefits. Nanjing Taidun Marine Equipment Engineering Co., Ltd is highlighted as a leading manufacturer of these essential components, emphasizing their role in enhancing safety and efficiency during docking. The article also provides guidance on choosing, installing, and maintaining fender cleats, along with answers to common questions.

This article explores the pneumatic fender market, highlighting its growth, key drivers, and future trends. Nanjing Taidun Marine Equipment Engineering Co., Ltd plays a pivotal role in this industry, providing OEM services to global manufacturers. The market is expected to grow significantly due to increasing maritime trade and technological advancements, despite facing challenges such as high costs and environmental concerns.

Choosing the right size boat fenders is essential for protecting your vessel during docking. This article provides guidelines on selecting fender sizes based on boat length and weight, as well as tips for placement and maintenance. Understanding these factors will help ensure your boat remains safe and undamaged while moored.

This article provides a comprehensive guide on how to clean boat fenders effectively. It covers the importance of maintaining clean fenders, the necessary tools and materials, and a step-by-step cleaning process. Additionally, it offers tips for maintaining fenders and answers common questions related to fender care.

This article provides a comprehensive overview of Yokohama fenders, highlighting their design, applications, benefits, and the technology behind them. As a leading manufacturer, Nanjing Taidun Marine Equipment Engineering Co., Ltd emphasizes the importance of these fenders in enhancing marine safety and efficiency. Regular maintenance and compliance with international standards ensure their effectiveness in various marine operations.taidunmarine

Super Cone Rubber Fender: Ultimate Berthing Protection for Modern Ports & Vessels In the demanding world of maritime operations, the safety of vessels and port infrastructure is paramount. Berthing impacts are inevitable, but the damage they cause is not. This is where the Super Cone Rubber Fender p

Marine Fender Frontal Panels for the Port SafetyEvery day, colossal cargo ships, nimble tugboats, and luxury cruise liners navigate the world's ports. The delicate dance of bringing a multi-ton vessel safely to rest against a concrete dock is a high-stakes operation. One wrong move, one miscalculate

Mooring Bollards: The Unsung Heroes of Global Trade and Maritime Safety IntroductionWhat is a mooring bollard? Discover the critical role these powerful marine fixtures play in docking massive ships, ensuring port safety, and keeping global supply chains moving.Have you ever watched a massive contai

| Availability: | |

|---|---|

Features

High Energy Absorption and low reaction force

Wide range of standard and customize size

Unsinkable design even if skin is punctured

Low maintenance

Easy installation

Burst resistance

Colored UV resistant PU Skin

Protective chain and tire net

Toughest rubber skin is option

Large standoff distance

Applications

Ship to ship transfers

Navy Berths

Oil and gas tankers

General cargo

RoRo and ferries

Container vessels

Cruise ships

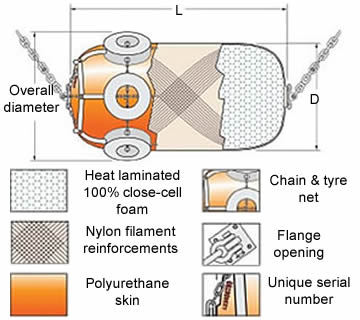

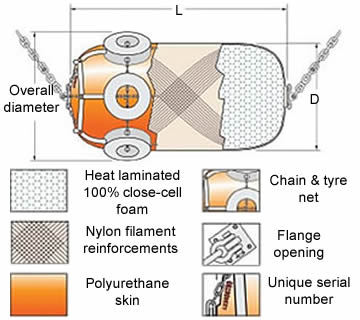

Foam fenders Structure

Foam fenders are fabricated with closed-cell resilient foam, with protective tough polyurethane elastomer skin(or tough rubber skin), reinforced with nylon filament, what’s more, protective chain and tire net is option for cushion foam fenders.

A. Foam filled fenders are filled with highest quality resilient closed-cell foam, this specification foam can provide high energy absorption with relatively low reaction force. Even the skin is punctured, it also is unsinkable without absorbing water, with our unique laminating process, each foam core is integrity, the foam core cannot be ruptured when compressed.

B. Guard and Cushion Foam filled fenders’ skin is constructed of polyurethane elastomer which is reinforced with nylon filament. The polyurethane skin is the unique elastomer specifically for fender applications. More thick filaments and elastomer are applied to both ends to better resist the defection and shearing force.

C. Foam Filled fenders are comprised of through central steel tube and external load flanges distributed at each end. All end fitting are H.D.G. Except the through central pipe, all longitudinal chains are joined to Clevis eyes at both ends of the fender.

D. Foam filled fenders incorporate chain and tire net. The chain and tire net design uses heavy duty H.D.G chains, fitted with heavy duty ties at the net intersections. This chain and tire net carry the tensile load, minimizes stress on the fender skin.

E. Chain and net used for the netted type cushion type foam fenders.

F. Rubber foam fenders skin is protected by vulcanized rubber, it is more tough, and with higher performance.

Performance Data

Diameter x Length | At 60% Deflection | ||||

mm | ft | Energy Absorption | Reaction Force | ||

Ft-kips | Ton-mm | Kip | Ton | ||

700x1500 | 2.3x4.9 | 19 | 3 | 30 | 13 |

1000x1500 | 3.3x4.9 | 35 | 5 | 39 | 17 |

1000x2000 | 3.3x6.5 | 50 | 7 | 57 | 26 |

1200x2000 | 3.9x6.5 | 67 | 10 | 63 | 28 |

1350x2500 | 4.4x8.2 | 112 | 16 | 94 | 42 |

1500x3000 | 4.9x9.8 | 171 | 24 | 130 | 59 |

1700x3000 | 5.6x9.8 | 208 | 29 | 139 | 63 |

2000x3500 | 6.5x11.5 | 335 | 47 | 190 | 86 |

2000x4000 | 6.5x13.1 | 398 | 56 | 226 | 102 |

2000x4500 | 6.5x14.7 | 460 | 64 | 261 | 118 |

2500x4000 | 8.2x13.1 | 591 | 82 | 269 | 122 |

2500x5500 | 8.2x18.0 | 885 | 123 | 402 | 182 |

3000x4500 | 9.8x19.7 | 1365 | 189 | 516 | 234 |

3300x4500 | 10.8x14.7 | 1105 | 153 | 380 | 172 |

3300x6500 | 10.8x21.3 | 1786 | 248 | 614 | 279 |

Note:

Actual values with ±5% tolerance, due to variations in materials, temperature, tolerance and speed of compression.

Other size and capacity models, can do customized.

Hot Tags: Foam Filled Fender, Foam Fender, Foam Filled Fenders, Foam Boat Fender, Polyurethane-Covered Fenders, Closed Cell Marine Foam, Engineered Protection Fender Systems, Foam Filled Pu Fender, Foam Filled Pu Fender, Foam Dock Fenders, China, Customized, OEM, manufacturing company, manufacturers, suppliers, factory, for sale, price, made in China

Features

High Energy Absorption and low reaction force

Wide range of standard and customize size

Unsinkable design even if skin is punctured

Low maintenance

Easy installation

Burst resistance

Colored UV resistant PU Skin

Protective chain and tire net

Toughest rubber skin is option

Large standoff distance

Applications

Ship to ship transfers

Navy Berths

Oil and gas tankers

General cargo

RoRo and ferries

Container vessels

Cruise ships

Foam fenders Structure

Foam fenders are fabricated with closed-cell resilient foam, with protective tough polyurethane elastomer skin(or tough rubber skin), reinforced with nylon filament, what’s more, protective chain and tire net is option for cushion foam fenders.

A. Foam filled fenders are filled with highest quality resilient closed-cell foam, this specification foam can provide high energy absorption with relatively low reaction force. Even the skin is punctured, it also is unsinkable without absorbing water, with our unique laminating process, each foam core is integrity, the foam core cannot be ruptured when compressed.

B. Guard and Cushion Foam filled fenders’ skin is constructed of polyurethane elastomer which is reinforced with nylon filament. The polyurethane skin is the unique elastomer specifically for fender applications. More thick filaments and elastomer are applied to both ends to better resist the defection and shearing force.

C. Foam Filled fenders are comprised of through central steel tube and external load flanges distributed at each end. All end fitting are H.D.G. Except the through central pipe, all longitudinal chains are joined to Clevis eyes at both ends of the fender.

D. Foam filled fenders incorporate chain and tire net. The chain and tire net design uses heavy duty H.D.G chains, fitted with heavy duty ties at the net intersections. This chain and tire net carry the tensile load, minimizes stress on the fender skin.

E. Chain and net used for the netted type cushion type foam fenders.

F. Rubber foam fenders skin is protected by vulcanized rubber, it is more tough, and with higher performance.

Performance Data

Diameter x Length | At 60% Deflection | ||||

mm | ft | Energy Absorption | Reaction Force | ||

Ft-kips | Ton-mm | Kip | Ton | ||

700x1500 | 2.3x4.9 | 19 | 3 | 30 | 13 |

1000x1500 | 3.3x4.9 | 35 | 5 | 39 | 17 |

1000x2000 | 3.3x6.5 | 50 | 7 | 57 | 26 |

1200x2000 | 3.9x6.5 | 67 | 10 | 63 | 28 |

1350x2500 | 4.4x8.2 | 112 | 16 | 94 | 42 |

1500x3000 | 4.9x9.8 | 171 | 24 | 130 | 59 |

1700x3000 | 5.6x9.8 | 208 | 29 | 139 | 63 |

2000x3500 | 6.5x11.5 | 335 | 47 | 190 | 86 |

2000x4000 | 6.5x13.1 | 398 | 56 | 226 | 102 |

2000x4500 | 6.5x14.7 | 460 | 64 | 261 | 118 |

2500x4000 | 8.2x13.1 | 591 | 82 | 269 | 122 |

2500x5500 | 8.2x18.0 | 885 | 123 | 402 | 182 |

3000x4500 | 9.8x19.7 | 1365 | 189 | 516 | 234 |

3300x4500 | 10.8x14.7 | 1105 | 153 | 380 | 172 |

3300x6500 | 10.8x21.3 | 1786 | 248 | 614 | 279 |

Note:

Actual values with ±5% tolerance, due to variations in materials, temperature, tolerance and speed of compression.

Other size and capacity models, can do customized.

Hot Tags: Foam Filled Fender, Foam Fender, Foam Filled Fenders, Foam Boat Fender, Polyurethane-Covered Fenders, Closed Cell Marine Foam, Engineered Protection Fender Systems, Foam Filled Pu Fender, Foam Filled Pu Fender, Foam Dock Fenders, China, Customized, OEM, manufacturing company, manufacturers, suppliers, factory, for sale, price, made in China